MICROIMP PRODUCTS

IMPLANT CONNECTION SOLUTIONS

Innovative solutions for the construction of implant-supported and/or implant-retained prostheses

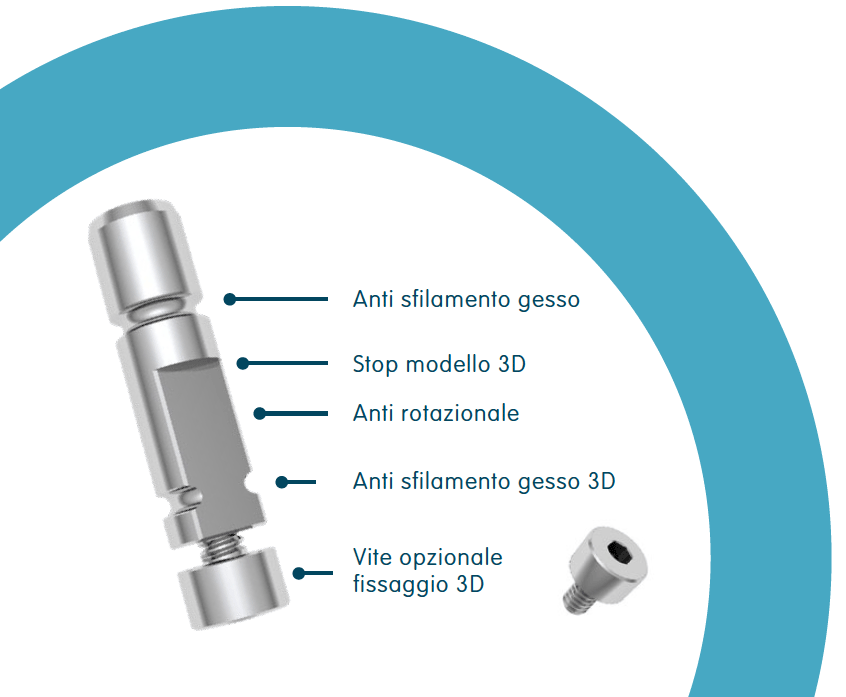

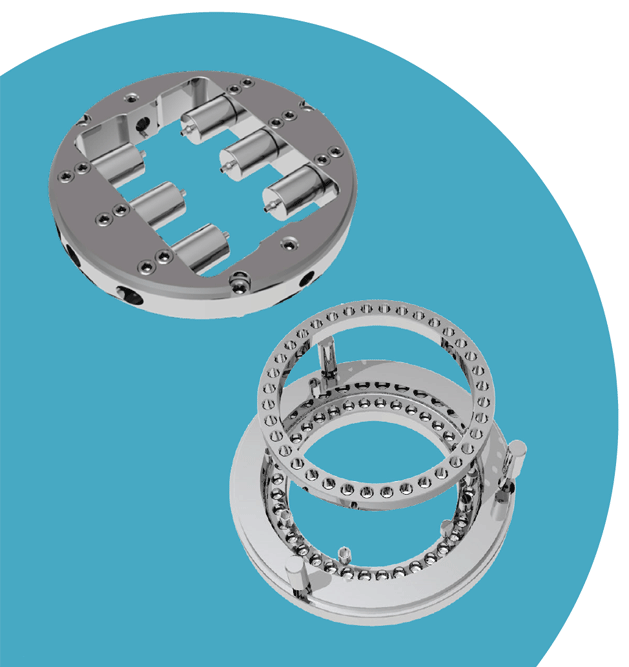

All Microimp analogues are made of AISI 303 (Austenitic Stainless Steel) to guarantee the quality of the connection and internal thread over time, compared to the same aluminium article.

Each analogue has an anti-rotation face always oriented to the geometry of the Fixuture, an anti-loosening circular notch (for plaster models) or and elevation stop (for 3D printed or milled models) and a locking screw on the bottom (on request) so it has all the features to be used by laboratories for different types of work.

For 3D printing, Microimp can provide a test file with a buffer to measure the printing error, which can vary due to many factors.

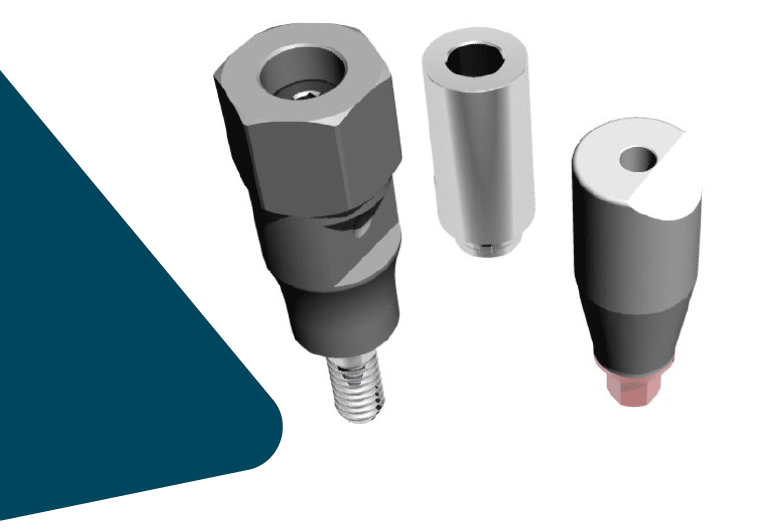

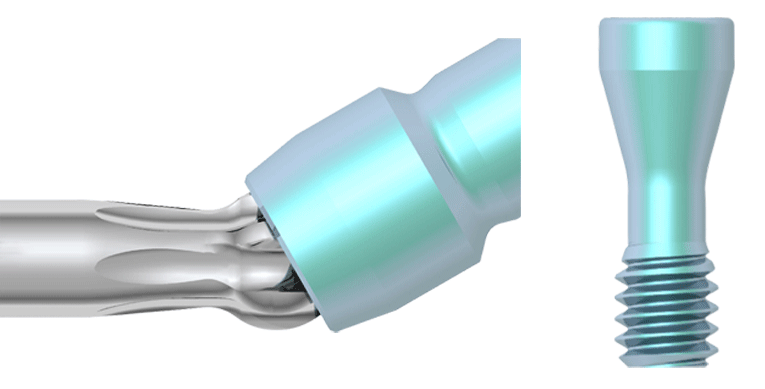

Titanium T-Base with gold surface treatment.

This device is usually assembled by means of glue to frameworks made of Zirconium, Lithium Disilicate, PMMA, Peek, Microimp produces these in 2 heights 4 mm and 6.5 mm in the 4 mm version we also have the rotational version for prosthesis on more implants where there is the request that the framework is screwed directly to the Fixuture.

T-Base in Cr.Co

The use of this T-Base with respect to Titanium is based above all on being assembled to a framework made of chrome cobalt, either by gluing or fixed with laser welding. This allows us to bind an absolutely precise device to the prosthesis and a screw seat suitable for the same screw that is always supplied with the T-Base.

Microimp produces 4 types of Scan Marker

Universal Scan Marker in Peek (Normal Scan)

The Universal T-Base Scan Marker fits all T-Bases manufactured by Microimp and together with its T-Base can be used for CAD construction of any artefact.

Metal (Sandblasted Ergal) Scan Marker (Esa Scan)

The Metal (Sandblasted Ergal) Scan Marker screws directly onto the analogue for more accurate scans and fits in the CAD environment, for both assembled and directly milled parts, each Scan Marker has tested and controlled tolerances of +/- 6 μ

The Intraoral Scan Marker (Ceramic Peek)

Screws directly onto the implant or analogue, recommended for intra-oral scanning, the screw is imprisoned in the implant, the material does not need to be sprayed with opacifiers and can be sterilised.

Scan Marker for tactile scanner (AISI 303),

Microimp is the only company in the world to mass-produce this type of locator, which screws directly onto the analogue, for those who need to use a touch-scanner to scan or correct an optical scan for complex multi-implant work.

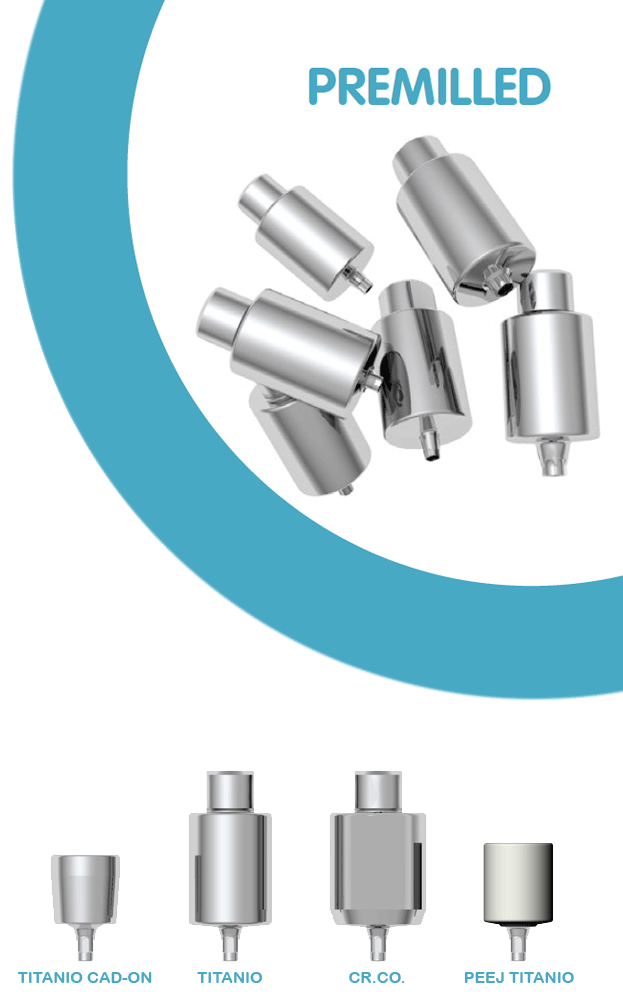

A class IIb semi-finished medical device, manufactured with numerically controlled machine tools, Microimp guarantees and certifies according to CE standards both the implant connection and the screw, included in the package.

Premilled Titanium Cad-On (Titanium Gr. 5 medical)

This type of Premilled can be milled without any sealing witnesses remaining after its processing, as the fixation takes place on its connection, which facilitates its processing also on the incisal or occlusal surface. This type of Premilled is suitable for those who wish to make the Cad-On system (double file) the simultaneous machining of both the abutment and the crown extrapolated from a single CAD file. Also with this type of product, customised T-Bases for customised shoulder management and trans-mucosal lengths can be produced. Millable with machine tools (CNC) with coolant

Premilled Titanium (Long) (Titanium Gr. 5 medical)

Premilled Titanium (Long) Always provided with connection and screw seat already machined and certified. Millable with machine tools (CNC) with coolant, for abutments directly screwed to the implant. These have a universal machine grip, after machining the workpiece the pin or gripping witness must be removed.

Premilled Cr.Co.

Premilled Chrome Cobalt Always provided with connection and screw seat, this can also be milled with machine tools (CNC) without coolant (Dry), for crowns directly screwed to the implant, to be veneered with ceramic or other materials.

Premilled Peek & Titanium

Microimp is the first company in the world to market this product in 2015. Easily machined with small 3-4 or 5-axis machine tools, even dry, this product guarantees elasticity and strength, as well as excellent aesthetics, especially in the anterior areas. Each Titanium Premilled must have its own machine grip holder.

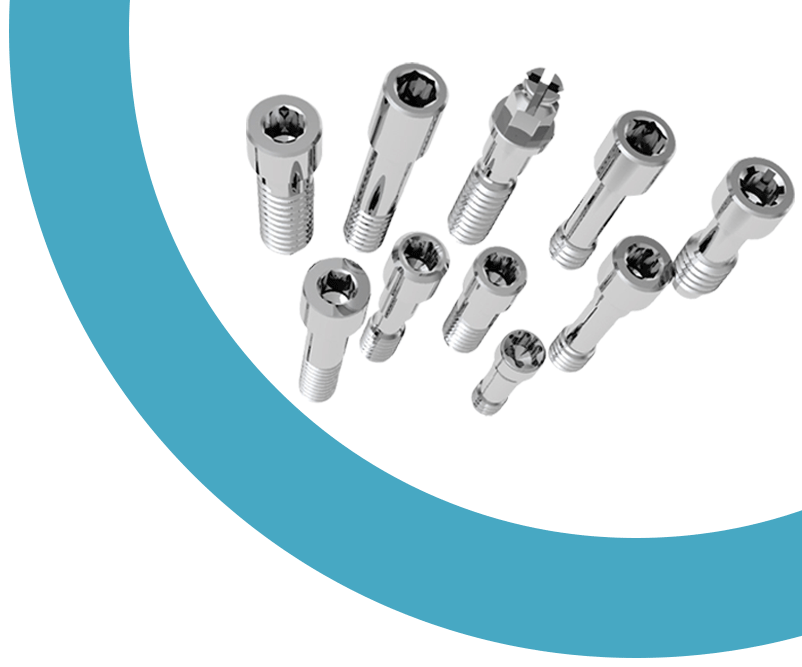

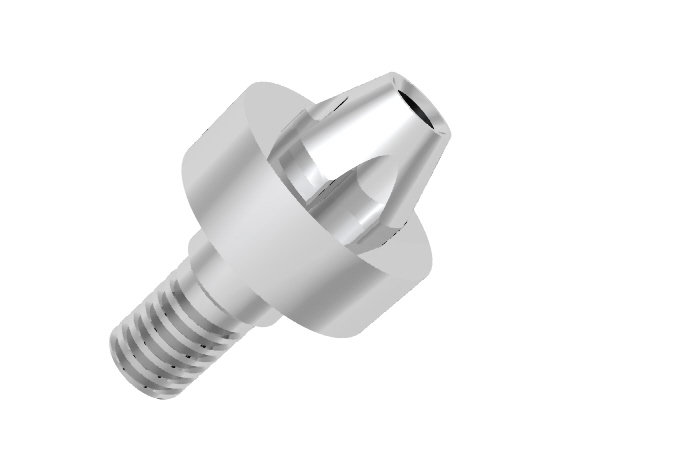

All Microimp screws are made of medical grade 5 titanium and respect the original screws in their shape and pitch. Their Screwdrivers engagement according to the implant manufacturer can be of different types, such as Hexagonal ( 1.20 1.25 1.30) Torx® ( usually used by Straumann ® ) or Unigrip, this engagement mostly used by Nobel Biocare ®.

Each screw is individually tested and all screws have an indication of the tightening forces to be applied ( see table ).

Microimp recommends not using the prosthetic screw, which is delivered with the prosthesis, during the working stages, so as not to alter the mechanical properties that a new screw possesses.

These screws have all the mechanical characteristics of prosthetic screws, differing only in the engagement on their head to accommodate the 'Screwdrivers' screwScrewdrivers with gimbal head. This peculiarity allows, despite the inclination, a good grip and consequently the possibility of being able to tighten the screw to the implant.

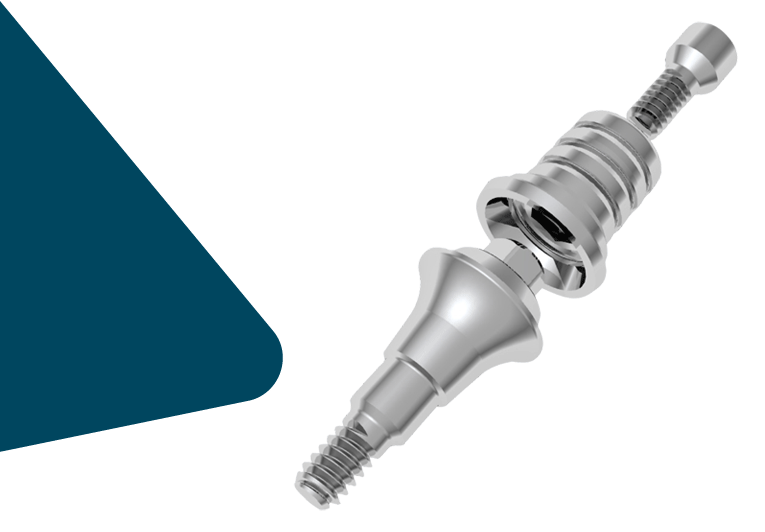

Microimp manufactures the Multi Unit Abutments with connection and the classic ø 4.8 diameter for all the implant houses in the catalogue, both in straight and angled versions 17° and 27°.

The straight version having a connection with hexagonal geometry also offers OTC®'s 'One Time Connection' solution for directly screwed single crowns, with the possibility of handling various transmucosal heights 1-2-3- mm.

The low-profile 1.2-mm taper allows use in limited interocclusal spaces and the 20° taper facilitates framework placement and passive fit.

Angled abutments remain the simplest solution for implants with steep inclinations and therefore necessary for insertion of the prosthesis in complete passivity.

The entire MUA range has prosthetic components for any type of solution.

The OTC one abutment-one time protocol is suggested to minimise peri-implant crestal bone resorption and improve soft tissue stability at the abutment implant interface. The MUA of the final desired transmucosal height can be screwed in with the special screwScrewdrivers at the time of implant insertion

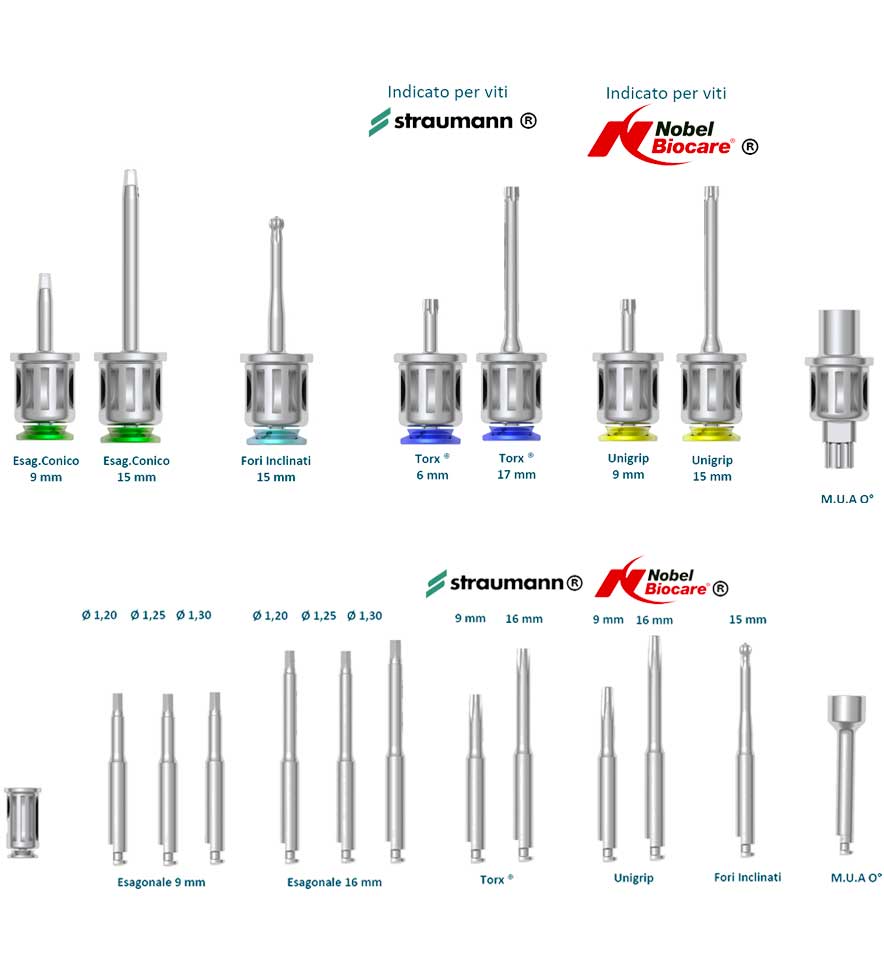

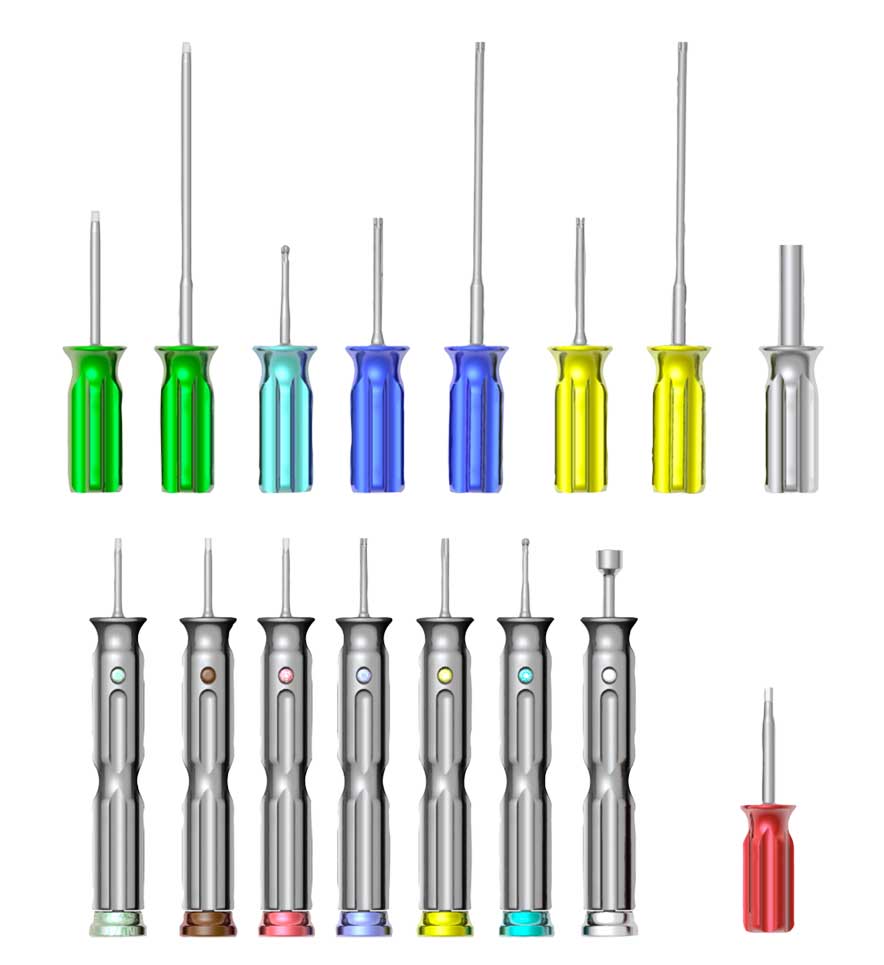

Microimp produces different types of Screwdrivers for the dental practice, for screw connections among the most commonly used in the prosthetic implant field:

Screwdrivers with already inserted tips: (long and short)

Hexagonal: suitable for screws with hexagonal connections ø 1.20-1.25-

Torx® suitable for Straumann® type screws

Unigrip suitable for Nobel Biocare® type screws

For slanted hole

For straight MUAs 0 degrees

Microimp produces different types of Laboratory Screwdrivers, for screw connections among the most used in the prosthetic implant field:

Screwdrivers with already inserted tips: (long and short)

Hexagonal: suitable for screws with hexagonal connections ø 1.20-1.25-1.30

Torx® suitable for Straumann® type screws

Unigrip suitable for Nobel Biocare® type screws

For Inclined Hole

For straight MUA 0 degrees

Driver with interchangeable tips (Ergal ergonomic handle and AISI 303 Tempered tips)

Hexagonal: (long and short) ø 1.20-1.25-1.30

Torx® suitable for Straumann® type screws

Unigrip suitable for Nobel Biocare® type screws

For Inclined Hole

For straight MUA 0 degrees